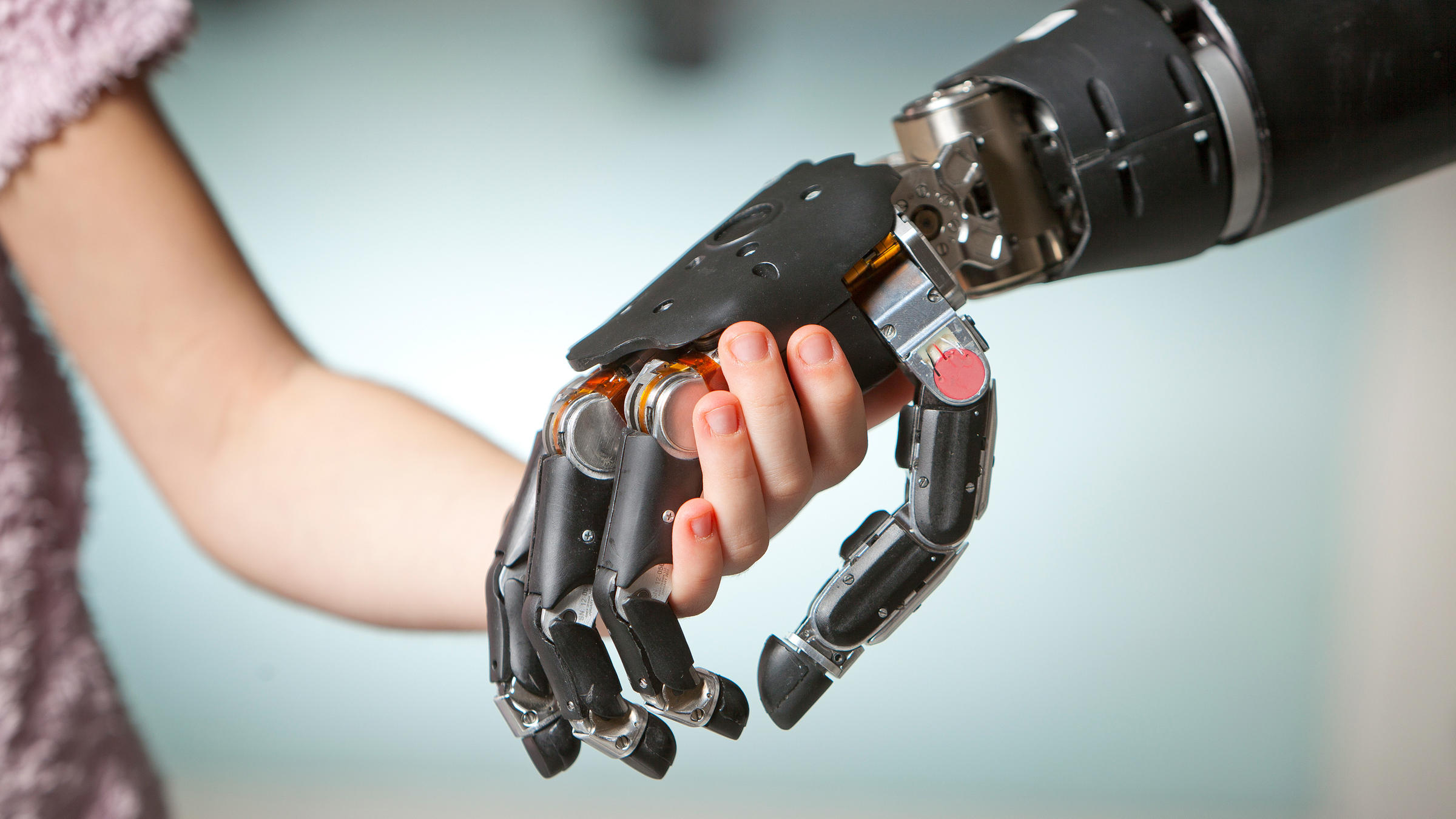

The bebionic3 has 14 different grips and is delicate enough to hold an egg

Wired, March 2013

Nigel Ackland can open beer bottles, pour drinks into a glass and delicately crack eggs into mixing bowls. So far, so normal. But the former precious metals smelter, who lost his right arm after an accident involving an industrial blender, tackles these tasks wearing a prosthesis, the bebionic3. The bebionic3 is manufactured by RSLSteeper, a Leeds-based assistive-technology company, and is the latest incarnation of a versatile and realistic artificial hand it first developed in 2009. Electrodes in a socket that fits over the user’s stump detect changes in voltage caused by the remaining muscles contracting and relaxing, and send signals to a CPU built into the unit. This controls servo motors in the four fingers and thumb, which change the hand’s shape.

“There are 14 different grips,” says Bruce Rattray, 42, bebionic3’s product manager. “From a fist to a finger-point.”

The CPU on the hand monitors each finger’s position through the rotation of its motor, enabling the hand to take up the shape of the object it is holding. “Every finger knows where the other fingers are,” says Rattray.This versatility leads to some impressive manoeuvres. Ackland can type, pick up heavy objects and beckon someone, and be adept in the kitchen, all by contracting and relaxing the muscles in his upper arm.

“It takes people about 15 minutes to get the hang of it,” says Rattray, though he admits Ackland’s egg skills take practice. A single limb costs between £8,000 and £10,000 for the components. Manufacturing can double that. Rattray says the company is working on miniaturising the design and increasing the number of grips the hand is capable of. “And then,” he says, “we start moving on from the hand to giving movement to the wrist and the elbow.”